Primary Data Collection

Questionnaire

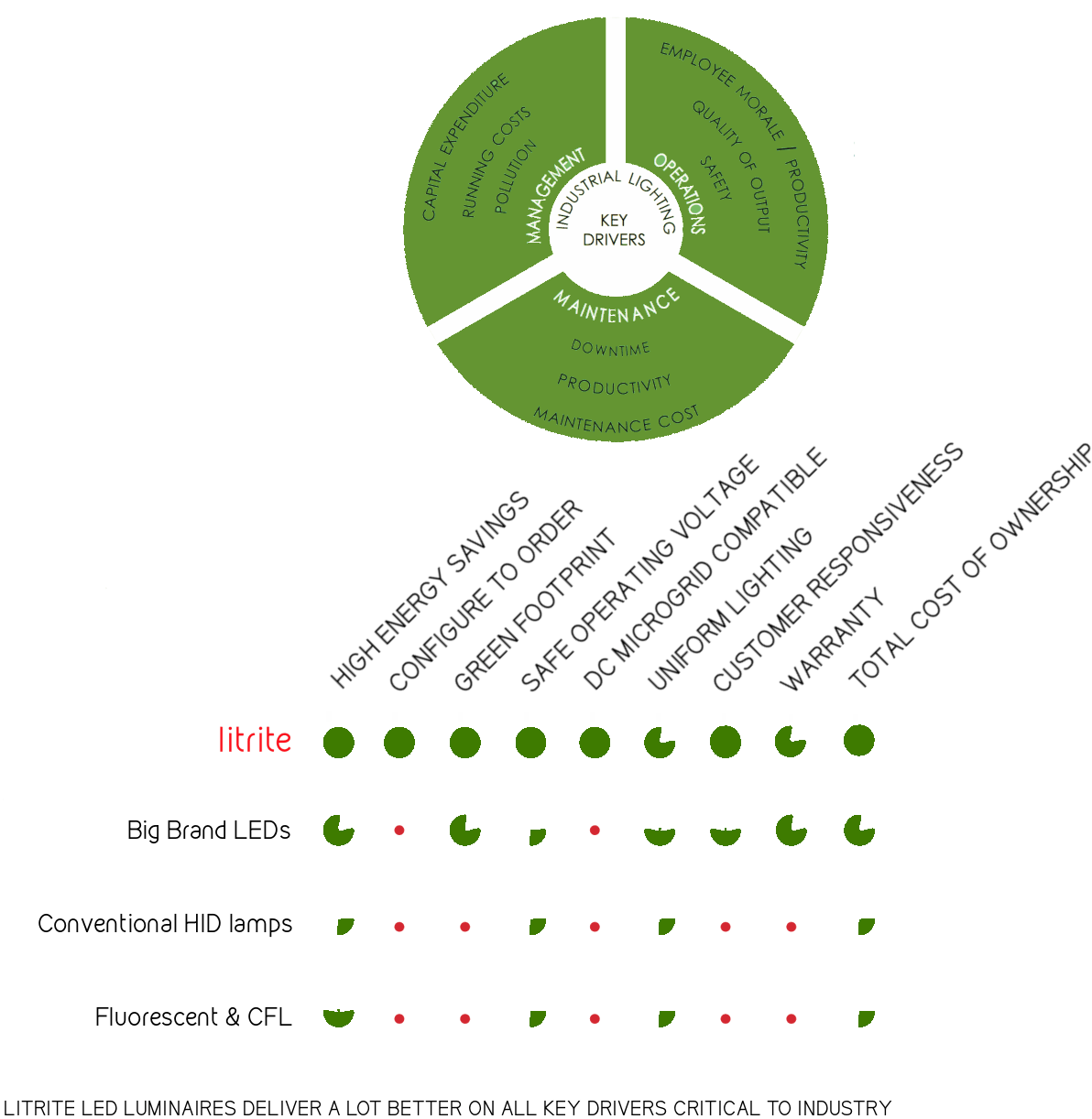

conventional lighting is a slow bleeding drain on your resources and our environment.

most LEDs luminaires in India are not designed ground up - they do not take advantage of everything the technology offers.

download product brochure

Designing the right size for each module, and the choice of LED power density in the module influences product performance.

Indiscriminate use of cheaper high-power LEDs without considering its influence on system functionality has been among the prime reasons for product failure in the field. We have seen this happen and our module design is primarily influenced by a number of experiences shared by customers and end users.

Application and not ease-of-production should influence module design.

LEDs are inherently directional light sources. A good design leverages this.

Deep understanding of photon kinetics with reflectors, lenses, diffusers and protective covers is not just necessary but highly critical in optic design.

Any kind of material in the path of light reduces lumen effciency. Poor design can cause efficiency losses as high as 30%.

End use requirements such as luminous intensity, colour temperature and glare thresholds should influence the choice of optics. Often retrofit LED luminaires compromise this very critical aspect.

Often of the least concern of most luminaire manufacturers, but the most important of all is the thermal dynamics of a fully assembled system.

A direct influencer of led life (lumen maintenance) it is very critical to take a systemic view to thermal design.

Optimizing conductive, convective and radiative heat transfers is critical.

An appropriate choice of led driving current based on sting level binning will also directly influence the thermal outcome.

Variation in product functionality or specifications based on customer application, deployment needs and usage should not be a deterrent to delivering to these needs.

Delivering the capability to let demand freely influence the manufacturing process without increasing supply chain complexity or compromising cost-of-production is our key design differentiator.

The heart of a luminaire is the power supply. It has a number of critcial electronic components that are subject to the vagaries of line surges and fluctuations that are usually unpredictable, especially in India.

End user experiences have clearly demonstrated that it is not the led's but almost always the power supply that fails.

A robust, fail-safe design is very critical with a current limiting design, OVP and capacitors that are military grade with long service life.

Application and installation conditions have to be taken into account to determine final connected design.

Ability to deliver the exact lumen needed by adding or removing modules as needed, and controlling input current at the module level.

Delivers the capability to get the exact output needed ('watt' you want) as opposed to using the available fixed-wattage luminaires from the competition.

Delivers Uniform Illumination and allows flexibility in deployment.

The only Industrial Luminaire to get a Class III certification.

Safe Low Voltage (<60VDC) using Class 2 isolated driver.

Safe to touch under dry conditions.

Easy to install and maintain.

Can run on DC micro-grids, the future of locally generated power.

Can be configured to run in a distributed arrangement to deliver higher driving efficiencies. This arrangement also delivers more uniform lighting.

Delivers the highest lumen / kg of material used as compared to any other luminaire.

A typical 120 W LED luminaire weighs over 7kgs, mainly due to the heavy heat sink required, often due to poor choice of leds and mis-aligned thermal design. Litrite delivers better thermal performance at less than half that weight.

Lowest Total Cost of Ownership (TCO) stemming from

- Very high efficiencies at the luminaire level

- Use of higher efficacy bin LEDs from top brands like CREE, Nichia and Bridgelux.

- Sensible choice of optics reduces the lumen losses in reflectors, lenses and covers.

- Very High efficiency drivers contributes further to imroved wall-plug efficiencies

- Better thermal management results in lower running temperatures that translates to longer life.

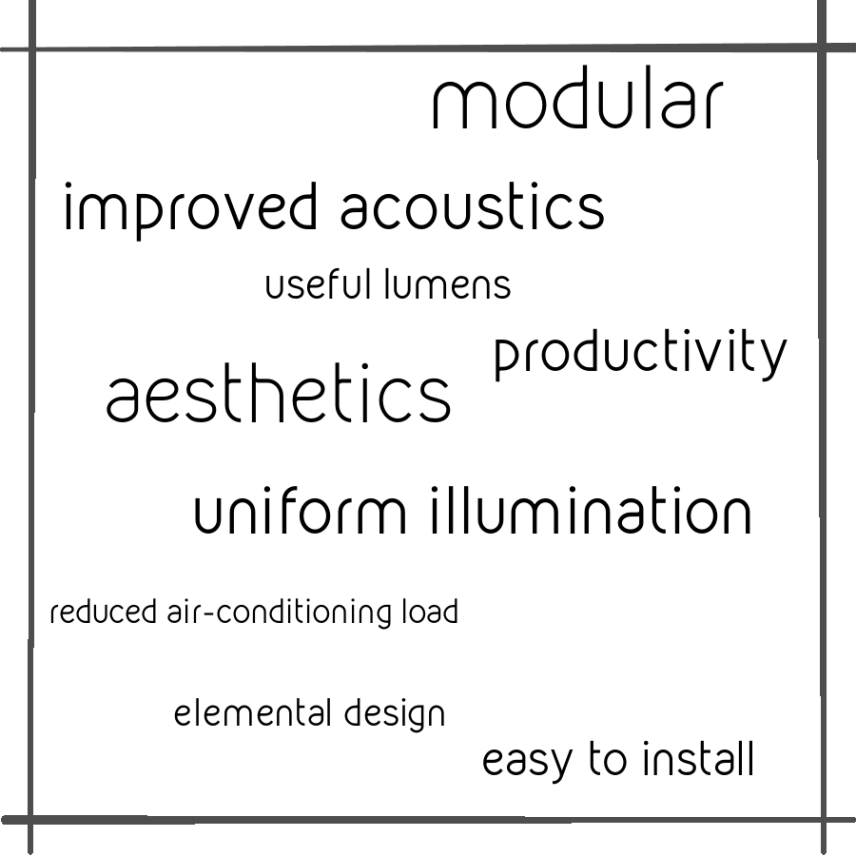

the litrite grid lighting system

- delivers a highly uniform lighting that no existing design can achieve

- delivers more useful light exactly where it is needed

- facilitates contiguous grid panels and a uniform grid ceiling

- optimized the room acoustics as lighting does not take up any grids

- optimizes reflectances with contiguous ceiling panels

- allows a clear space above the grid for utilities and air-conditioning

- is easy to install both in existing and greenfield situations

Questionnaire

Record Measurements

Understand Site Constraints

Conduct End User Interviews

Conduct Stakeholder Interviews

Baseline

Assumptions

Goals

Simulation

Savings Calculations & Payback

Total Cost of Ownership Calculations

Options

Recommendation

Presentation & Discussion

Agreement

Letter Of Intent / Purchase Order