Lighting Audit (contact us for a free audit)

Record Measurements

List Site Constraints

Conduct End User Interviews

Conduct Stakeholder Interviews

-> Fix Baseline

-> List Assumptions

-> Identify Priorities

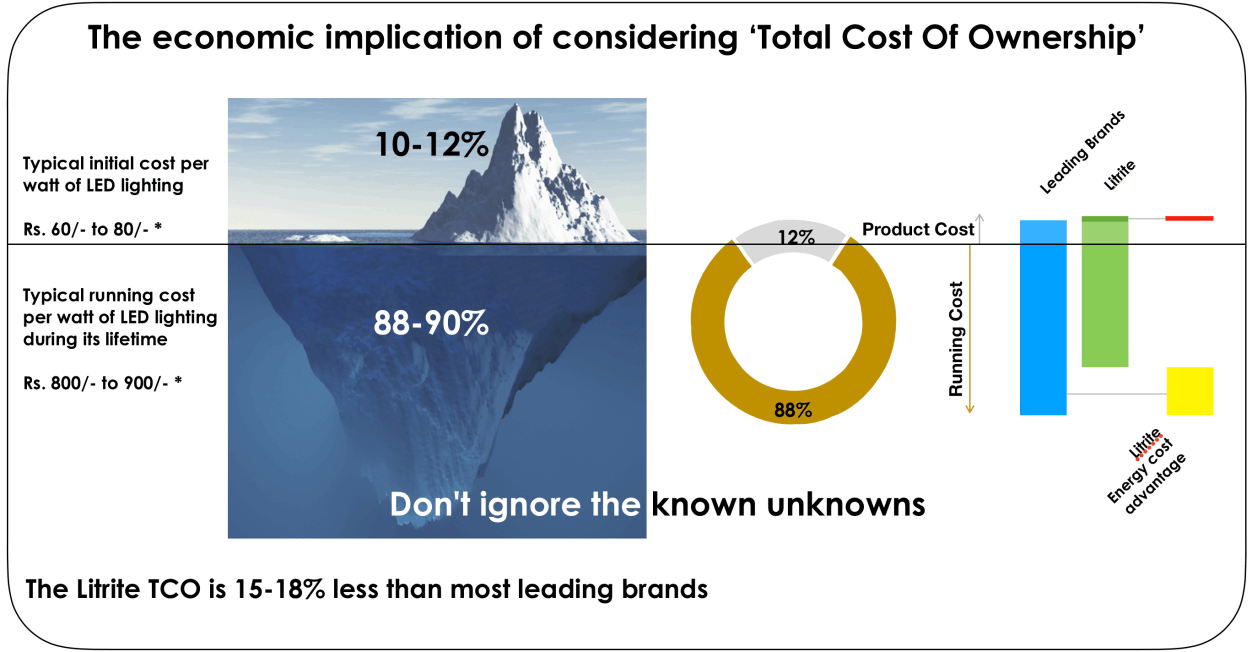

Most purchase decisions are focussed on upfront costs.

Due to their long life nearly 90% of the cost in LED illumination is incurred after the purchase.

Focus on the running cost not on the product cost.

Weigh the miniscule higher product cost (red) against the substantially lower energy cost (yellow) you will save during the luminaire's lifetime.

The impact of running cost on total-cost-of-ownership is considerably more than the initial cost. So paying a bit more for better efficiency translates to substantial TCO reduction.

Use our TCO & Payback Calculator on this page and see for yourself

Record Measurements

List Site Constraints

Conduct End User Interviews

Conduct Stakeholder Interviews

-> Fix Baseline

-> List Assumptions

-> Identify Priorities

Understand Lighting Terminology

Ask the Key Questions

Get Luminaire Technical Details (ies files)

Perform Lighting Simulation & Optimize

-> Identify Luminaire Options - Type and Number

Get Commercial Offers

Calculate & Compare Total Cost of Ownership (Use our Calculator)

Compare Payback Period

-> Identify Optimal Solution

Presentation & Discussion

Agreement

Letter Of Intent / Purchase Order

At an LED emitter level the bin from which the LEDs are sourced by the luminaire manufacturer has a direct influence on the final Wallplug Efficiency and hence will directly impact your Total Cost of Ownership / Payback Period. This typically varies from 120 lumens/watt (for lower bin and lower priced LED emitters) to 200 plus lumens/watt at the top end of the bins which are expensive. The efficacy is specified at given standard test temperatures as specified by .

The total or Wallplug Efficiency of the luminaire is the most critical piece of information to obtain from the manufacturer or dealer. If this information is not being provided, ask for the Total Lumen Output of the luminaire under ambient (running) conditions, and divide this by the input wattage specified. In case of LED lighting, the wallplug efficiency as of this writing typically ranges from 80 lumens/watt (low quality, low price) to 140 plus lumens/watt in case of very high quality LED luminaires.

Lenses : What brand of lenses are uses ? What are the lenses made of - Polycarbonate / Acrylic / Others ? What is the refractive index of the material used ? What % of incident light is transmitted ? Are they UV protected in case there will be UV exposure to the luminaires ?

Reflectors : Are specular or diffuse reflectors used ? What is the rationale for the choice ? What is the reflectivity of the material ? Is accelerated ageing test done on them ? Are the reflective surfaces coated with UV resistant material in case there will be UV exposure to the luminaires ?

Covers - Clear or Diffuser : What is the transmissivity of the covers used for protection or diffusion of light ? Are they UV protected in case there will be UV exposure to the luminaires ?

Luminaire life with LED technology advancing rapidly mostly boils down to the life of the driver. More often than not LED luminaires stop working due to driver/power-supply-unit failure.

What brand of drivers are used ?

What temperature rating are the capacitors (usually the first to fail) ?

Secondly the question to ask is about the efficiency of drivers. If it is anything below 87% the drivers can be called as sub-optimal as very high efficiency drivers are available today. Efficiencies of top end are above 90% and can go up to 94% as of this writing..

The drive current at which the luminaire is being actually run compared to the optimal drive current specified by the LED chip manufacturer will influence the lumen extraction efficacy of the system.

While a higher drive current may be allowed as per the specification of the LED manufacturer. Many manufacturers drive the LED's at the maximum allowed current to keep their LED costs low (fewer LEDs driven are higher current can deliver the same output)- this can affect you as an end used in two ways:

A. A higher current means a robust thermal design in the luminaire is critical. Without this there is not only loss of efficiency (higher TCO) but also reduced life.

B. A higher current also means the LEDs run at a lower efficacy due to the inherent Physics of semiconductor devices. This translates to lower efficiency for you, and hence higher TCO.

We are all used to referring to the cost of luminaires in terms of watts of power. i.e. Cost / Watt. This is OK when comparing conventional lighting, but not appropriate when comparing LED lights.

Conventional lights like metal halides are a mature technology and have ‘typically’ very similar efficacies across brands, but this is not the case with LEDs. LEDs are an evolving technology with rapid improvements being seen in the average lumen/ watt delivered. Factors that affect the delivered efficiency of luminaire are already listed in the questions above:

LED Efficacy

-The concept of ‘binning’ which is unique to solid state electronics like LED chips means that the same manufacturer of LED chips will offer a higher efficacy chip at a higher price.

Luminaire Efficiency

-The luminaire efficiency depends on three key factors:

a. Thermal Design

b. Optics Efficiency

c. Driver Efficiency

For comparing different LED luminaires determining the cost/lumen is key. Only that will bring all products to a reasonably accurate common dinominator. Many manufacturers do not provide this data directly and the average buyer tends to fall back to comparing cost/watt. Yet other manufacturers hide it behind jargon or even show the LED efficacy as the luminaire efficiency which couldn't be further from the truth

The intensity of light in the visible spectrum per unit area of the surface on which it is incident.

Evaluate your 'Lux' requirement based on the type of task and user age.

Evaluate requirements for both vertical and horizontal surfaces.

UNIT: Lux (Lumens / Sq.Meter)

The total light output of a luminaire in the visible spectrum measured using an integrating sphere or goniophotometer in lumens.

When comparing LEDs please get the total lumen output of each luminaire in Lumens at typical operating ambient temperature..

UNIT: Lumens

Colour Corrected Temperature or CCT is the colour appearance of the light emitted by luminaire as related to the color appearance of a reference source that is heated to that particular temperature in degree.

Warm White 2500-4000 K

Neutral White 4000-5000 K

Cold White 5000-6500 K

UNIT: Kelvin (K)

Colour Rendering Index or CRI is a quantitative measure of the ability of a light source to reveal the colors of various objects faithfully in comparison with an ideal light source like the sun.

In simple terms a CRI of 80 means the light source is able to reveal 80% of the colors that an ideal light source would.

UNIT: R

The total number of hours that the luminaire continues to provide the rated lumen

output measured by lumen maintenance tests (LM70) and extrapolated into future hours.

L70 is the time taken in hours for the luminaire output to drop to 70% of its original lumen output.

UNIT: Hours

The output 'Total Lumens' divided by the total input power to the luminaire.

The efficiency depends on the --> LED Emitter Efficiency

-> LED Bin

-> LED Temperature

-> LED Driver Efficiency

-> LED Optics Efficiency

UNIT: Lumens/Watt.

The junction temperature of the LEDs in the luminaire.

If there is improper thermal management the LEDs will run at temperatures higher than their design permits results in shortened Useful Lifetime and lower Wallplug Efficiency.

It is known in the industry that every 10 degree increase in LED junction temperature reduces life by half.

TCO or Total Cost of Ownership is the total running cost of the luminaire over its useful lifetime.

TCO depends on

-> Initial Cost

-> Luminaire Useful Life

-> Maintenence Cost

-> Energy Cost

-> Energy Cost Inflation Forecast

Cost of maintenance includes the

-> Cost of Luminaire/Ballast being replaced

-> Manpower/Labour Cost for replacement

-> Work Downtime during replacement

The number of months taken to recover the investment made in the new LED system through energy cost saved.

Payback Period depends on

-> Initial Cost

-> Maintenence Cost

-> Energy Cost

-> Energy Cost Inflation Forecast

-> Hours of Usage / Period

LEDs are inherently directional in nature. In other words the light emitted from an LED is in a specific direction and not in all 360 degrees as in case of conventional lighting.

This means more 'useful' lumens are emitted in the direction where light is needed by LEDs.

Separated Extra Low Voltage or SELV is a standard that classifies the electrical equipment based on the fact that any human contact under dry conditions will not cause any harmful electrical shock.

The protection is delivered by

A) Isolating the supply from the equipment and

B) By keeping the output voltage below 60 Volts DC.

Most LED luminaires are not designed ground-up. They neither leverage the positive aspects of this new technology nor design around its inherent limitations.

Retrofit LEDs are a compromise - they seem simpler to install but undermine long term benefits that LED technology brings to the table.

Industrial luminaires are usually Class I or Class II and need to pass more stringent safety tests, and require more engineering.

10 - 15 % more efficient than leading Indian brands of LED, delivering a compelling total-cost-of-ownership.

litrite is elementally designed by applying basic Physics to LED technology resulting in a solution that maximizes the advantages (directionality, efficiency, solid state and longevity) while obviating its limitations (heat, current control and cost/lumen).

litrite is a Class III luminaire operating at below 60V DC with an isolated power supply system that delivers SELV (separated/safe extra-low voltage) making them safe-to-dry-touch.